What is HDPE?

Why is HDPE Widely Used in Outdoor Furniture?

- Durability and Weather Resistance

- Low Maintenance

- Sustainability

- Design Flexibility

Comparison of HDPE with PVC, PE, and Resin

|

Property

|

HDPE (High - Density Polyethylene)

|

PVC (Polyvinyl Chloride)

|

PE (Polyethylene)

|

Resin

|

|

Density

|

High density (0.941 - 0.965 g/cm³), providing strength and durability

|

Medium density (1.35 - 1.45 g/cm³), relatively rigid

|

Low density (0.910 - 0.940 g/cm³), flexible and less strong

|

Varies widely depending on the type of resin, can be low - density (e.g., epoxy resin is often denser than PE)

|

|

Weather Resistance

|

Excellent resistance to UV radiation, moisture, and temperature extremes. Does not degrade easily outdoors

|

Good weather resistance but may become brittle over time with prolonged sun exposure. Can release harmful chemicals when burned

|

Moderate weather resistance, may degrade more quickly than HDPE when exposed to UV rays for extended periods

|

Varies; some resins are highly weather - resistant (e.g., polyurethane resin), while others may require additional treatment for outdoor use

|

|

Chemical Resistance

|

Highly resistant to a wide range of chemicals, including acids, alkalis, and solvents

|

Resistant to many chemicals but can be attacked by strong oxidizing agents. May release chlorine when exposed to fire

|

Resistant to most chemicals but less resistant than HDPE. Can be affected by some solvents

|

Varies depending on the resin type; some are highly chemically resistant, while others may be more susceptible

|

|

Durability

|

Strong and durable, with high tensile strength and impact resistance. Resistant to cracking, warping, and splintering

|

Rigid but can become brittle and crack over time, especially in extreme temperatures. Prone to scratching

|

Less durable than HDPE, more flexible and prone to deformation under stress

|

Varies; some resins can be very durable when properly formulated and cured, while others may be more fragile

|

|

Maintenance

|

Low maintenance; only requires occasional cleaning. Does not need painting, staining, or sealing

|

May require periodic cleaning and may need to be protected from sharp objects to prevent scratching. Some types may require special cleaning agents

|

Moderate maintenance; may need to be protected from UV rays to prevent degradation. Can be more difficult to clean if it absorbs dirt or stains

|

Varies; some resins are easy to clean, while others may require specific cleaning and maintenance procedures

|

|

Cost

|

Moderate cost, relatively affordable considering its durability and performance

|

Cost - effective, often less expensive than HDPE but may require more frequent replacement due to lower durability

|

Generally less expensive than HDPE, but its lower durability may offset the cost savings in the long run

|

Varies widely depending on the type of resin; some high - performance resins can be very expensive, while others are more affordable

|

|

Sustainability

|

100% recyclable. Many manufacturers use recycled HDPE in production

|

PVC is recyclable but the recycling process is more complex and less common. It can release harmful chemicals during production and disposal

|

Recyclable, but recycling rates are relatively low. Some types of PE are made from non - renewable resources

|

Varies; some resins are biodegradable or made from renewable resources, while others are less sustainable

|

|

Aesthetic Appeal

|

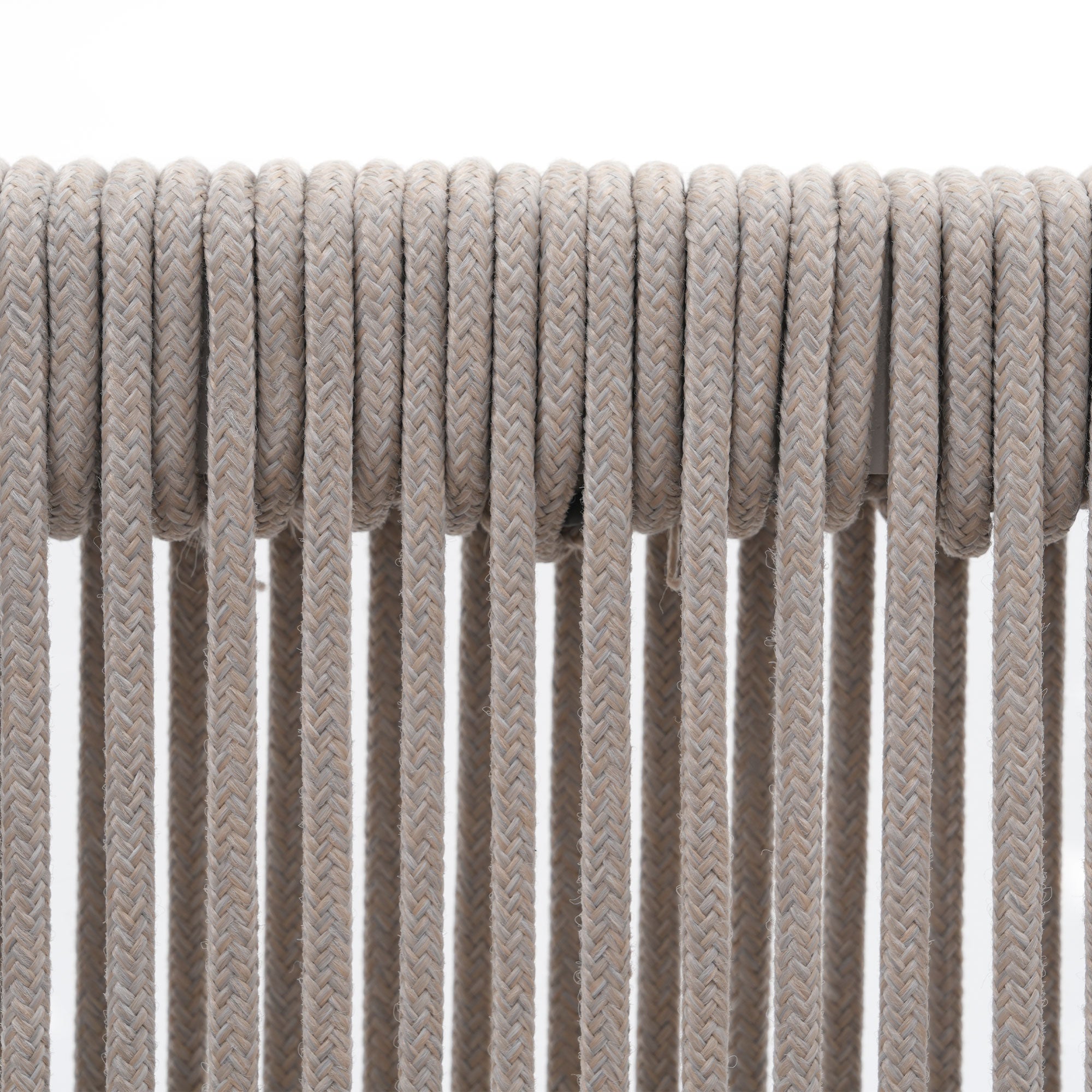

Can be molded into various shapes and colors. Can mimic the look of other materials like wood or wicker

|

Available in a wide range of colors and textures. Can be used to create detailed and decorative designs

|

Limited in terms of color and texture options compared to HDPE. Often used for more functional rather than decorative applications

|

Highly customizable; can be pigmented, textured, and shaped into intricate designs. Some resins can achieve a very high - end and luxurious look

|